Grinding Machine (Parts And Functions) हिन्दी YouTube

Dec 30, 2016· Grinding Machine (Parts And Functions) हिन्दी ... LEARN AND GROW 631,875 views. 10:41. ... Shaper Machine | Major Parts and their function in details Duration: ...

WhatsApp)

WhatsApp)

Dec 30, 2016· Grinding Machine (Parts And Functions) हिन्दी ... LEARN AND GROW 631,875 views. 10:41. ... Shaper Machine | Major Parts and their function in details Duration: ...

A wide variety of parts of grinding machine options are available to you, There are 94,607 parts of grinding machine suppliers, mainly located in Asia. The top supplying countries or regions are China, Taiwan, China, and Japan, which supply 99%, 1%, and 1% of parts of grinding machine respectively.

Facts About a Surface Grinding Machine Bhavya Machine Tools. Mar 15, 2013 ... Know the facts about surface grinding machine including the uses of ... are very important in industries and these are used for making parts and...

optical profile grinding machine is used in making of tool and Die. It acts an important part. it gives high accuracy grinding looks like ordinary grinding machine but it gives high finishing and ...

Major Parts of the Universal CenterType Cylindrical Grinder Major parts of the machine include the bed, slide, swivel table, headstock, footstock, and wheelhead. Bed The bed is the main structural component and is responsible for the rigidity of the machine tool. The bed supports the slide, which in turn supports the swivel table.

The main part of the grinding machine is the bed. The bed is the basic support of the grinding machine, and is equipped with a grinding wheel frame, a work table, a head frame, a tailstock and a lateral sliding saddle. Keep these parts in exact relative position while working.

Skip to main content. Try Prime EN Hello, Sign in ... Jade Grinding Machine, Jewelry Jade Polishing Machine, 7Speed Adjustable Chisel Carving Machine, 110V Electric Gem Engraving Cutting Milling Bench Grinder Table Saw Polisher Set (Black) 139. 99. FREE Shipping.

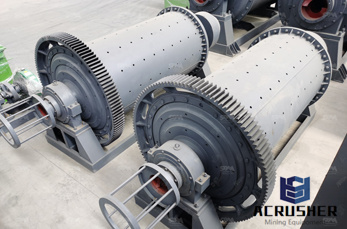

Jun 07, 2019· Have Some Essential Facts about Grinding Machine and Their Types. The Grinding machine is those kinds of machines that grind various kinds of materials. Many industrial systems use grinding machines to grinding their hard materials in bulk. A grinding machine is a machine tool that has a harsh wheel as its main part.

Jul 16, 2018· A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting. There are various grinding machine types, each with a different purpose. Here''s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas.

main parts of grinding machine main parts of grinding machinexinhai global cupping. main parts of grinding machine main parts of grinding machine Grinding machine. 2019 5 15 · A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool.

Apr 06, 2015· Rough grinding machines; Precision grinding machines; Rough Grinding Machines. The rough grinding machines are used to remove stock with no reference to the accuracy of results. Excess metal present on the cast parts and welded joints are removed by rough grinders. The main types of rough grinders are. Hand grinding machine; Bench grinding ...

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.

Grinding machines can be used for grinding with high precision and surface roughness, as well as for highly efficient grinding such as strong grinding. History of grinding machine In the 1830s, in order to adapt to the hardening of parts such as watches, bicycles, sewing machines and firearms, the United Kingdom, Germany and the United States ...

A cylindrical grinding machine may have multiple grinding wheels. Here the work piece is rotated and fed through the wheels to form a cylinder. It is widely utilized to manufacture accurate objects like tubes, rods, bushings, bearings, and other parts. An efficient surface grinder may be .

In this post, you learn the grinding machine and grinding machine operation, types of grinding wheel and more. Grinding Machine. A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface quality. Grinding machine is a type of machine used to grind the workpieces.

Grinding Machine Definition: A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.. It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.. Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.

Parts for Grinding Machine manufacturers offer high quality Parts for Grinding Machine to meet all your Parts for Grinding Machine you are looking for high quality Parts for Grinding Machine and reliable manufacturers, please click the links below to obtain detailed information, and send Parts for Grinding Machine inquiries.

Dec 01, 2016 · Parts of the machine • The main parts of the pedestal grinder are the: Body Grinding wheels Work rests and Guards 8. Body • The body is made of boxlike construction of cast iron and forms the main component of the machine 9. Grinding Wheels • These are used for metal removal and are available in all shapes and sizes.

Throughout the grinding wheel''s history, the bond that holds the abrasive grains together has proven as important as the grains themselves. The success of grinding wheels began in the early 1840s, when bonds containing rubber or clay were introduced, and by the 1870s a bond with a vitrified or glasslike structure was patented.

Grinding machines and metal cutting machines are both used for the manufacture of finished products. This project is focused on the functions of the parts used in the makeup of grinding machines and metal cutting machines. The project was proposed as an investigation of the high price of grinding machines.

This vise, which is part of a table, or carriage is moved back and forth under the abrasive wheel. The surface grinder can cut steel in pieces no bigger than 18" long by 6" high by 8" wide. The table of the grinder is also magnetic, which aids in holding the material still.

Start studying ME2653 Exam 4. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... The first grinding machines were made by Brown and Sharpe in the 1860s for the grinding of parts for what device? ... True or False: With centerless grinding, no distortion of the part occurs dues to grinding forces. Therefore, it ...

Major Component Surface Grinding Machine . Major Parts of the Universal Center Type Cylindrical Grinder Major parts of the machine include the bed, slide, swivel table, headstock, footstock, and wheelhead. Bed The bed is the mainponent and is responsible for the rigidity of the machine tool. more+

CNC grinding machines, NC grinding machines All industrial ... Find all the manufacturers of cnc grinding machines and contact them directly on ... With this family of machines we cover a range of parts to grind . .... The corundum, or CBN, grinding wheel is used for grinding at the main and pin bearings. Get Price

WhatsApp)

WhatsApp)