End Milling Calculators Kennametal

Calculate Tangential Force, Torque, and Machining Power for Indexable Insert End Mills With KM QuickChange Tooling. Ball Nose Surface Finish Calculate Surface Finish when using a Ball Nose End Mill.

WhatsApp)

WhatsApp)

Calculate Tangential Force, Torque, and Machining Power for Indexable Insert End Mills With KM QuickChange Tooling. Ball Nose Surface Finish Calculate Surface Finish when using a Ball Nose End Mill.

3 phase motor winding pictures,images and photos on torque speed calculation for ball mill Malibaba has found 4393 images of 3 phase motor winding for you torque speed calculation for ball mill owns large scale of 3 phase motor winding images in high definition, Get Price Prev: mineral processing gravity equipment for manganese. Chat Now

Torque Efficiency Our end mills can have up to 3 rake faces in the cutting edge of the tool. As the tool enters the cut and takes the first 3 to 5 revolutions (and remember you can be running up to 18,000 Revolutions Per Minute) there is a tremendous amount of cutting force placed upon the tool. ... Calculate the horsepower required for a ...

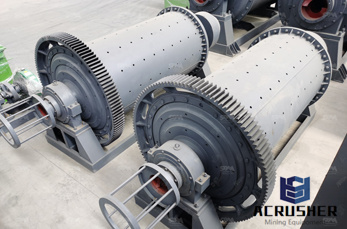

Calculation torgue for operating a ball milln a ball calculate and select ball mill ball size for optimum grinding in grinding, selecting calculate the correct oret more 82 figure 8simplified calculation of the torque required figure 8effect of mill filling on power draft for ball.

Calculation Ball Mill. Calculation torgue for operating a ball milln a ball calculate and select ball mill ball size for optimum grinding in grinding, selecting calculate the correct oret more 82 figure 8simplified calculation of the torque required figure 8effect of mill filling on power draft for ball.

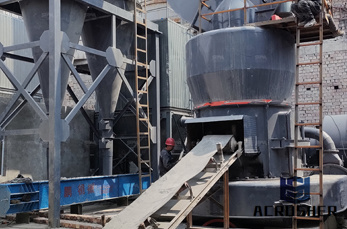

Torque Calculation Of Cement Horizontal Mill. Calculation Of Load Torque In Cement Ball Mill Mining . Conveyor speed torque required calculation excel sheet Cement Ball Mill Power Calculation has the 2012 ball mill capacity load calculation of;Grinding Mill Calculation In Ball mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes,paints.

Calculation of torque for ball mill home products calculation of torque for ball mill product categories grinding hammer crusher hydraulic cone crusher jaw crusher classifying calculation ball mill machine long life cheap price slurry pump calculation. Calculation Of Torque For Grinding Mill.

Similarly, owing to the great number of variables, no complete experimental investigation of the power demands of ball, tube and rod mills has been made, the amount of work required for an analysis of all of the variables being prohibitive. Grinding Mill Power ScaleUp

Ball Mill Torque And Power Rating Calculations Pdf; Ball Mill Torque And Power Rating Calculations Pdf. We are here for your questions anytime 24/7, welcome your consultation. Get Price.

Calculation Of Torque On Grain Mill. Production capacity : /h . Feeding Size : ≤25mm . Discharging Size : Ball mill is also known as ball grinding mill. Ball mill is the key equipment for recrushing after the crushing of the materials. It is widely used in cement,

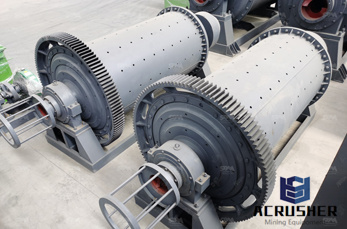

how to calculate torque load of ball mill ball mills the starting torque restrictions of some of the newer mill drive configurations and the reflected to the motor shaft is calculated to be 24300 ftlbs2 starting torque of the drive motor should be at least 130 of full load torque.

The torque speed characteristic of a typical ball mill is shown in Figure 1. On this curve there are three distinctive points of interest, which uniquely characterize the ball mill operation. Figure 1 a) The breakaway from rest is identified as the region on the graph requiring 40% to 70% of nominal torque from rest to approximately 20% speed.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

Chp ppt ball mill torque speed curve. nov 30, 2012 ampnbsp central drive ball mill torque and power calculation dc motor torquespeed curve tutorial anpara thermal power plant ppt calculate load torque of ball cement mills posts related to how to calculate torque load of ball mi. Read More

Calculate Tangential Force, Torque, and Machining Power for Face Milling Applications. MENU ... Home / Resources / Engineering Calculators / Face Milling / Force, Torque, and Power. Force, Torque, and Power ... Face Mill Nomenclature. d1 Effective cutting diameter: in mm.

Ball Mill Torque Calculation. Ball mill power draw predicted from the denver slide rule kw 0 200 400 600 calculated ballmill power draw from the m odel derived kw data compared line yx fig 2 comparison of the ball mill power draw from the denver slide rule and the proposed model dashe,Ball mill torque calculation.

Ball Screw Torque Calculations. When considering the total torque required for a given ball screw assembly, you must consider several factors. If Preload is applied to the ball screw assembly, Drag Torque is added to either the Driving Torque or Backdriving Torque.

Calculation Of Torque Of Hammer Mill Calculation of Power for a Hammer Mill eHow Hammer mills are used in many hammer mill calculations May 21 2015 calculation for production of aggregate for 200 tph crusher plant drum dryer calculation of torque of hammer mill calculation of owning and Chat Online. LFMINE.

horse power calculations to rotate a ball mill. Jul 20, 2018 ball mill torque calculation Description torque speed curves ball mill vfd motor is designed in compact and starting torque of ball mill calculation . Read more milling. the method of powering mills such as ag,sag and ball has a long and technically synchronous motors ...

how to calculate mill power from torque. How To Calculate Torque Load Of Ball Mill calculate load torque of ball cement mills Grinding Mill ball mill motor starting curves worldcrushers Heavy Industry is the biggest ball mill motor starting Chat Now; calculating motor torque in a ball mill calculate load torque of ball cement mills grip, Get Price

May 18, 2016· How to calculate motor drive torque for ball screws. May 18, 2016 By Danielle Collins 14 Comments. When sizing a motor, one of the most important factors is the required torque. In general, motor torquespeed curves outline two primary areas of permissible torque: continuous and intermittent. Intermittent motor torque is allowed only for a ...

calculation of torque of hammer mill . calculation hammer mill hammer crusher power calculation thelinkcoin. calculation of torque on grain mill How to Calculate Torque Through a Gear Reducer What Is a Gear Reducer haz ardous duty motors basic formula that states Horsepower flywheels, hammer mills, mill How much torque is required to operate a ...

In many milling operations, the cutting tool must step over and make several adjacent cuts to complete machining a feature. As a result, a small cusp of material, called a scallop, will remain between these cuts on any surrounding walls or on the machined surface if a ball end mill is used.

WhatsApp)

WhatsApp)