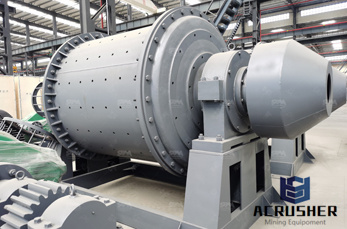

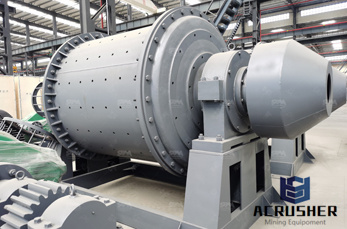

Raw Mill In Cement Plant,Cement Making Plant

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and end products in cement plant.

WhatsApp)

WhatsApp)

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and end products in cement plant.

The OK™ mill has been FL''s standard cement VRM since 1993. Since its introduction the OK mill has proven to be the most efficient cement VRM available with the highest reliability and ease of operation. In 2017, FL introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement mill.

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is .

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

Vertical roller mill with peak raw, cement and slag grinding performance. Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity.

mining ore vrm raw mill process ewagsorg. Raw Mill Vrm Process And Function Of All raw mill vrm process and function of all Grinding Mill In Vrm Process vrm process operation manual instructions for coal mill loesche raw advantages of using ball mill over VRM Gold Ore Crusher advantage over a ball mill coal mills of thermal .

Feb 10, 2016· Maintenance costs high for VRM and low for Ball mill ; Process control/process technology ball is operation friendlt and simple in operation but VRM requires some PID or control technology. Plant/system auxiliaries less auxillaries in ball mill and hydraulic circuit to be maintained for VRM .

Raw Mill for sale, Raw Mill Process, Raw Mill Machine. Raw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and other materials metallurgy, mine, chemical and construction Besides, it has two forms of milling, one is an open form, and the other is a recycle close form, Chat Now

May 15, 2013· Vertical raw mill pradeep kumar 1. Vertical raw KUMARSr G M OperationKarikkali WorksChettinad Cements Ltd 2. The principle of vertical millresembles like ammi kallu, attaankallu,Or ennai chekku vandi 3. History of grinding technology 4.

vertical raw mill process Mine Equipments. Raw Mill In Cement PlantCement Making Plant Crusher Machine A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement The grinding process is controlled to obtain a powder with a broad particle size range in which typically 15 by Vertical Roller Mill . PROCESS ...

vertical roller mill 75 tph, Roll Mill Loesche Vertical Roller Mill, raw mill loesche 696 lokswasthyasewaorg. More Products; raw material want to crush or grinding loratradexin. technical or calcined pure alumina fines, Vertical roller mill for raw materials In the vertical roller mill which is widely used in the raw material grinding .

that of a vertical roller mill (VRM) carrying out the same oper ations by a factor of between and 2, depending on the degree of optimisation of the ball mill. Fig. 1 illustrates this connexion, as well as showing the increasing energy benefit that can be obtained with a vertical roller mill as the specific Blaine surface area rises.

Vertical Raw Mill Vrm 96. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalent. The ...

Nov 16, 2011· Process in vertical raw mill. 1967 Shelby GT500 Barn Find and Appraisal That Buyer Uses To Pay Widow Price Revealed Duration: 22:15. Jerry Heasley Recommended for you

Feb 17, 2016· In this training module, we''ll cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw feed. We''ll describe the general arrangement ...

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

vrm roller raw mill maintenace process for coal mill vrm in cement industry. vrm roller raw mill maintenace the standard for grinding raw materials in the cement manufacturing Mills for Raw, Coal, Vertical Roller Mill In Cement [More] Energyefficient grinding .

Mill vrm designs for raw, fuel and cement grinding for several ok mill has been fls standard cement vrm since its introduction, the ok mill has proven to be the most efficient cement vrm available, with the highest reliability and ease of 2017,.

MVR vertical roller mill with MultiDrive ... an unintended stop of the grinding process is practically excluded. No matter what type of material has to be ground – cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a ...

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purpose. ...

How To Control Residue In Vertical Roller Mill For Raw Meal ... In Standard Operating Process For Raw Mill In In Cement Industry raw meal raw... Get Price. Application of Statistical Process Control for Coal Particle Size. vertical roller mill of AS Cement Factory (Turkey) were investigated using control ... size, control charts, process ...

OK mill The most reliable and efficient mill for raw and. Mill VRM designs for raw fuel and cement grinding for several decades The OK mill has been FL''s standard cement VRM since 1993 Since its introduction the OK mill has proven to be the most efficient cement VRM available with the highest reliability and ease of operation In 2017

WhatsApp)

WhatsApp)