Benefits of Using Abrasive Blasting Before Surface Coating ...

Abrasive blasting is an important part of surface coating preparation, ensuring that the surface will hold a protective coating and halt maintenance issues.

WhatsApp)

WhatsApp)

Abrasive blasting is an important part of surface coating preparation, ensuring that the surface will hold a protective coating and halt maintenance issues.

Cryogenic grinding/milling with liquid Learn more about our other other gas and technology the major benefits of cryogenic grinding are the Over three decades of laboratory and plant experience . .

Air Products'' PolarFit ® cryogenic grinding solutions can help you grind more effectively and efficiently, particularly for heat sensitive or toughtomill materials. Whether you have an existing cryogenic or ambient milling system that you need to upgrade, or plan to install a new system, we can help.

grinding under the aspect of surface integrity and attainable accuracy. Although, hard turning is a more flexible, more environmentally friendly and higher throughput alternative to grinding, process reliability and surface quality is still considered behind grinding processes due to issues related to geometrically defined cutting tools [KLO 05].

The Pelleting Process For many years, pelleting was considered an art, a process involving imprecise measurement, uncertain results, and that undefinable quality of feel. This socalled "art" of pelleting came about in an environment lacking the understanding of the effects occurring when the differing

The Difference Between Casting Forging. Casting is the process where metal is heated until molten. While in the molten or liquid state it is poured into a mold or vessel to create a desired shape. Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state.

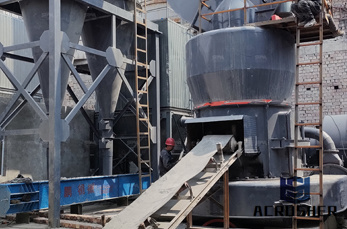

Grinding Mill. XSM grinding mills vary from coarse grinding, medium grinding to micro fine Mill(Grinder Mill)is widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials materials include line, calcite, barite, coal, gypsum, mica and bentonite powder.

benefits of grinding over other process. benefits of grinding over other process advantages disadvantages grinding process Shanghai Grinding Mill XSM grinding mills vary from coarse grinding, medium grinding to micro fine grindingGrinding Mill(Grinder Mill)is widely used in metallurgy, building materials, chemicals, mining minerals in areas ...

The entire process took only a few minutes, with a few injections on either side of my face, placed directly into my jaw muscles. It didn''t hurt really (and you can believe it—I''m a wimp), and it was over before I knew it. "You won''t start to notice results for a week or two," she told me, and I left with hope for a clenchless future.

Adding Dependents to Your VA Benefits If you''re receiving disability compensation from us, you may be eligible for an increase in benefits to help support your family. Veterans who have a 30% or higher disability rating can add eligible dependents to their compensation benefits to get a higher payment, also known as a "benefit rate."

Flaxseed is becoming more popular, because of its high protein content and high omega3 oil content (similar to salmon and other fatty coldwater fish). Flax seed is one of the best meals to grind yourself, as it is best ground just before use. Flax seed when ground can go rancid in as little as one week, and so it is worth grinding at home.

On the other hand, stump removal involves pulling the stump from the ground. Normally, it requires the heavy use of force, and the machines employed have highpower requirements. In essence, the process of stump grinding is preferred for many reasons. It is far easier to execute and uses efficient tools to get the job done.

Dec 01, 2003· The grinding process involves more variables—type of grinding wheel, wheel speed, infeed rate, wheel dressing frequency, dressing method, type of coolant and so forth—than most other metalworking processes. There are so many variables, in fact, that controlling the grinding process .

If you hear your grinder slowing down or stuttering as you grind, stop grinding and check for any parts of the pumpkin seeds stuck on the blade. Carefully dislodge the seed and continue grinding. Add pumpkin seed powder to your pancake batter, oatmeal, workout shake or cold cereal to boost the protein content.

Throughout the fineblanking process pressure is constantly applied to both sides of the part achieving flatness unmatched by conventional stamping. Flatness specifications typically are met right out of the press, without additional grinding or other operations. Form in Two Dimensions

Machining is a term used to describe a variety of material removal processes in which a cutting tool removes unwanted material from a workpiece to produce the desired shape. The workpiece is typically cut from a larger piece of stock, which is available in a variety of standard shapes, such as flat sheets, solid bars, hollow tubes, and shaped beams.

Breaking up cannabis is just a part of the smoking process. If you consider yourself a seasoned smoker, there''s a good chance you have a preferred technique to do so. Over the years the technology from two, to three, and now four chamber grinders have taken the market by storm, filling the shelves of head shops and online marketplaces.

Nov 15, 2018· Centerless Grinding: In the centre, less grinding the work piece is not provided with a fixed centre or any kind of chuck. The work piece rotates between two rollers; both the wheels rotate in the same direction with different wheel is known as grinding wheel and the other is known as regulating wheel.

Grinding is a subset of cutting, as grinding is a true metalcutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

Jul 20, 2017· The emergence of new, difficulttomachine materials has also caused many companies to implement grinding processes over other material removal technologies. However, proper grinding wheel selection is essential to ensure the required part quality, production rate, and .

Jun 28, 2015· One of the best investments a frequent smoker can make. Grinders speed up and simplify the process of separating dry herbs, and make it much easier to conserve your herbs when they are finely ground. When pulling herb apart by hand, pollen and other plant matter can stick to your fingers, reducing its potency. However,

Steels of different grades and specifications can be either hot rolled or cold rolled—including both basic carbon steels and other alloy steels. It may seem obvious, but some types of steel are better suited for certain applications. Knowing which to use can help avoid overspending on raw materials.

The CNC machine operator only needs basic training and skills, enough to supervise several machines. In years gone by, engineers needed years of training to operate centre lathes, milling machines and other manually operated machines. This means many of the old skills are been lost. 3.

Definition of grind in the Idioms Dictionary. grind phrase. ... by applying a combination of planning and foresight, combined operation grinders can offer major benefits. (Grinding) Hughes ... it should be noted that "grinding" is a misnomer and the process properly described is more of a "fracturing/cracking" of the coffee bean between ...

WhatsApp)

WhatsApp)