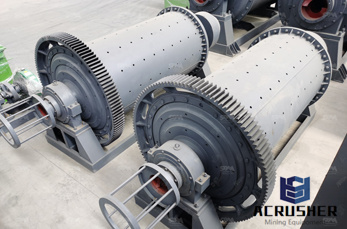

2 Tph Ball Mill Cement Ball Mill,CE Approved 900*1800 ...

Quality Cement Ball Mill manufacturers exporter buy 2 Tph Ball Mill Cement Ball Mill,CE Approved 900*1800 Mill Price from China manufacturer.

WhatsApp)

WhatsApp)

Quality Cement Ball Mill manufacturers exporter buy 2 Tph Ball Mill Cement Ball Mill,CE Approved 900*1800 Mill Price from China manufacturer.

Quality Mining Ball Mill manufacturers exporter buy 900x1800 Mining Ball Mill for Ore Cement Clinker Gypsum Glass from China manufacturer.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Small Scale Gold Mining Ball Mill 900*3000/china Ball Mill Prices/cement Mill Manufacturer, Find Complete Details about Small Scale Gold Mining Ball Mill 900*3000/china Ball Mill Prices/cement Mill Manufacturer,Small Ball Mill Prices,Gold Ore Grinding Mill Machine,Ball Mill Supplier In Germany Gold Ore Ball Milling from Mine Mill Supplier or ManufacturerLuoyang Zhongde Heavy Industries Co., Ltd.

Ball Mill. Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc. According to the need of customers, ball mills can realize both wet and dry production. Ball mills have been designed in standard sizes of the final products between mm and mm in ...

Jul 29, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Improvement of cement performances through the use of grinding aids ... outnumbering horizontal ball mills. Vertical cement mills are able to reach production values which are significantly higher than the ones achievable with traditional ball mills, in some cases up to 300 t/h. Empirically, It can be ...

A new ball mill circuit from CPB is not „old fashion"! (Mostly, it is the best solution for the customer.) Conclusion Ball Mill (closed circuit) Rollerpress with Ball Mill Vertical Mill CASE A CASE B CASE C Lowest operational cost Lowest investment cost Highest availability Higher flexibility by 2 grinding units Easiest maintenance

Jan 07, 2015· ~ Nael Shabana 20104~ Definition of Ball/ Tube Mill: Ball or tube mills are rotating steel cylinders where size reduction of the mill feed is performed by motion of the grinding media. Rotation of the mill cylinder raises the pile of mill feed and grinding media to an optimum high, necessary for grinding operation.

Jul 11, 2018· 900*1800 Small Ball Mill, Find Complete Details about 900*1800 Small Ball Mill,900*1800 Small Ball Mill,Small Sand Cement Ball Mill,900*1800 Small Ball Mill from Supplier or ManufacturerHenan Hongji Mine Machinery Co., Ltd.

Jan 11, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** ... A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been ... Separator motor 300 kW Separator Fan 248300 m 3/h ESP Fan 74100 m 3/h 497 mmwg 375 mmwg ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. specifiion of cement plant hammer crusher

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

300 To 7500 Tpd Ball Mill In Mini Cement Plant And Cement Clinker Grinding Plant For Sale, Find Complete Details about 300 To 7500 Tpd Ball Mill In Mini Cement Plant And Cement Clinker Grinding Plant For Sale,Mini Cement Making Plant For Sale,Cement Production Manufacturing Plant,Conveyor Belt For Cement Grinding Plant from Cement Making Machinery Supplier or ManufacturerHenan .

Ball Mill. Ball mill machine is widely applied in the industries, such as cement, silicate product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc. It is mainly used to make dry or wet powder grinding of various ores and other grindable materials. Working Principle Of Ball Mill:

Used 300 tpd White Cement Plant, FL Kilns and Mills, 60Hz ... 60Hz. Please inquire. 1,500,000 tpy Cement Grinding Plant, with 2 units 4200kW Cement Ball Mills, 50Hz. Feature Page. Complete 2 x 100 tph+ Grinding Plant X Cement Mills, shell supported on slide shoe bearings ... (2 units) Please inquire. 1750HP 895RPM ...

Feb 12, 2017· In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Cement ball mill/grinding mill/cement mill Shanghai Good Heavy. ... JMC is the manufacturer and supplier of ball mills used in cement industry, in India. . kiln, Jaw Crusher, ... mill for cement grinding The FL ball mill is designed for grinding of clinker. ... CEMENT MANUFACTURING TECHNOLOGIES. ... 100 TPD Cement Mill. Get Price

Feb 10, 2016· Mill(300350 – TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare with the product of a ball mill relative to these parameters.

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for overflow grinding.

300 to 7500 tpd ball mill in mini cement plant and cement clinker grinding plant for sale High Efficient Low Operation Cost Of 6000 tpd Mini Cement Plant Get Price Epc Contractor For 2500 Ton/day Cement Clinker Grinding Plant B Grinding Equipments List supplying for 2500 tpd Cement .

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore, copper ore, gold ore, bauxite, calcite, barite, gypsum and other minerals in mining, quarry, chemical, cement and other industries.. Ball mill is the necessary equipment in ore beneficiation plant.

WhatsApp)

WhatsApp)