Quality Ball Mill Liners Mill Liners Manufacturer

Wuxi Orient Antiwear Engineering Co.,Ltd. is best Ball Mill Liners, Mill Liners and Cement Mill Liners supplier, we has good quality products service from China.

WhatsApp)

WhatsApp)

Wuxi Orient Antiwear Engineering Co.,Ltd. is best Ball Mill Liners, Mill Liners and Cement Mill Liners supplier, we has good quality products service from China.

Cement – Tube mill internals – Shell liners LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry.

Quality We at Ashoka Machine Tools Corporation are Manufacturer of Mini Cement Plant, Sugar Plants, Herringbone Gear, Ball Mills and Gearbox, Axle, Sprocket Gear Parts since 1974 in Surajpur Site V, Greater Noida, Uttar Pradesh

We, Technomart Engineers Private Limited from 2015 are manufacturing a highquality range of Cement and Fertilizer products range consists of Cement Plant, Ball Mill, and Fertilizer Plant. All offered products are designed using quality tested material under the direction of our domain experts at wellequipped infrastructure unit.

PulpMax Composite Mill Liners are highperformance lightweight mill liners uniquely constructed with a rubber, ceramic matrix, and carefully selected highhardness steel inserts. Designed for a number of minerals processing applications, they are customisable to fit the specifications of your SAG or ball mill.

Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase ...

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Subscribe to International Cement Review. 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to News, Articles and HD Videos. £ 205 / US 315 / EUR 260

Nov 10, 2017· Cement mill se Judi jankari aur adik jankari pane के लिए हमारा चैनल लाइक करें और सब्सक्राइब ...

The ball mill is a key piece of equipment for grinding crushed materials, and is widely used in production of powders such as cement, silicates, refractory material, and glass ceramics, as well as for ore dressing of both ferrous and nonferrous metals. Ball mills can grind wet or dry and can be continuous or batch type mills.

Re: MonoChamber Ball Mill. Hi Fjalali, Thanks for sharing the more feed is d80 (80% passing size) of 4000 micron than calculated maximum ball size of 50 mm seems for such fine feed mono chamber mill a combination of lifting and classifying liner will be a good, there is no standard grinding media size distribution is available in ...

Ball Mill Liners are developed us using latest technology support and can be made available in standard. ... We offer a wide range of Cement Mill Liners . We use superior quality raw material to manufacture these castings. ... Cement Plant liners for raw mill, coal mill etc, hardfacing wear plate liners. Rs 110/ Kilogram Get Latest Price.

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

Mill SHELL Liner HEAD Liners. Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place. Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings.

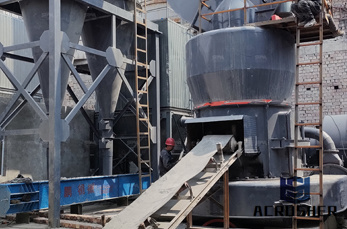

Cement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding. Cement grinding station can make full use of Industrial waste such as the slag, fly ash, furnace slag and coal gangue around the .

Parts Of Cement Ball Mill Liners tembaletu. cement mill lifter liner. China Mill Liners, Chute Liners, Wear Castings, Wear, Low Carbon Alloy Steel Mill Wear Resistant Spare Parts Rubber Liner Lifting Bar Lifter Bars Introduction The rubber lining plate is used to .

offers 3,180 ball mill liners products. About 46% of these are mine mill, 16% are mining machinery parts, and 1% are cement making machinery. A wide variety of ball mill liners options are available to you, such as astm, din, and jis.

Ball mill machines are widely used in the metal scrap crushing, mining crushing machinery, and chemical, cement and power generation plant machinery spare parts. JYS CASTING Ball Mill Liner JYS CASTING provides customised ball mill liners.

Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

Nozhasteelcom Crubro 4800 for liners plate of cement mill. ... and Exporter of Conveyors Cement Plant and Ball Mill offered by Super Tech ... concrete crushinbg ... Read More Liner Plate In Cement Mill

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small ...

We offer a full line of parts for rod, ball, and semiautogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners.

Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to ...

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected ...

WhatsApp)

WhatsApp)