mining process for kaolin

kaolin filter in mining process . Want to watch this again later? Sign in to add this video to a playlist. Process for producing kaolin product for paper coating: solution ...

WhatsApp)

WhatsApp)

kaolin filter in mining process . Want to watch this again later? Sign in to add this video to a playlist. Process for producing kaolin product for paper coating: solution ...

Kaolin Filter In Mining Process kaolin filter in mining process Kaolin Clay with the chemical Kaolinite Processing Get Price/Info mining process for kaolinite Get Price Online Kaolinite: The clay mineral kaolinite information and . Chat; Mining and Processing Kaolin citeseerxistpsuedu.

After mining, kaolin is crushed and slurried with water in a powerful disperser, or blunger. Here the pH is adjusted to neutral, and a dispersant is added. The slurry is then pumped to a gravity settling area or "drag box" where sand, mica, and other such impurities are removed. This process is .

Kaolin Mining In Middle Georgia. THE FALL LINE The origin of kaolin can be traced to the Cretaceous geologic period, about 70 million years ago when dinosaurs roamed the earth and much of the southern half of Georgia was covered by a great sea.

Kaolinite (/ ˈ k eɪ ə l ɪ n aɪ t /) is a clay mineral, part of the group of industrial minerals with the chemical composition Al 2 Si 2 O 5 is a layered silicate mineral, with one tetredral sheet of silica (SiO 4) linked through oxygen atoms to one octedral sheet of alumina (AlO 6) octedra. Rocks that are rich in kaolinite are known as kaolin / ˈ k eɪ ə l ɪ n / or china clay.

A REVIEW OF ENVIRONMENTAL CONCERNS Kaolin Clay Mining and Processing Reclamation Report Series 1989 2 July 1989 Prepared for the Kaolin Clay· Project by: Minnesota Department of Natural Resources Division of Minerals Reclamation Section 500 Lafayette Road St. Paul, MN 612/ Box567 Hibbing, MN 55746 .

A REVIEW OF ENVIRONMENTAL CONCERNS Kaolin Clay Mining and Processing Reclamation Report Series 1989 2 July 1989 Prepared for the Kaolin Clay· Project by: Minnesota Department of Natural Resources Division of Minerals Reclamation Section 500 Lafayette Road St. Paul, MN 612/ Box567 Hibbing, MN 55746 218/

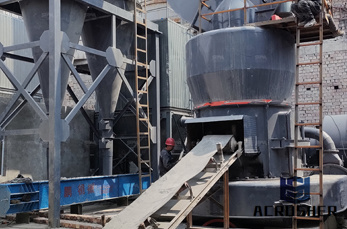

A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to .

A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit. Wet processing of kaolin begins with

Cu Pb Zn Dressing Process; Kaolin Mining Process; Titanium Mining Process; Chrome Ore Mining Process; Magnetite Separation Production Line; Gold Cip Production Line; Navigation Home . ... Ceramic Filter. Read More. Quickview. High Frequency Dewatering Screen. Read More. Quickview. Vacuum Filter. Read More. Quickview.

This chapter discusses the exploration, mining, and processing. Once a clay deposit has been discovered, a drilling program to determine the areal extent, thickness and type of overburden, and thickness and quality of the clay is initiated. Both core and auger drills are used in .

offers 14,824 kaolin mining products. About 14% of these are mine mill, 14% are mineral separator, and 2% are mining machinery parts. A wide variety of kaolin mining options are available to you, such as gravity separator, magnetic separator, and flotation separator.

kaolin mining and processing the role of iro kaolin mining and processing the role of iro kaolin jaw crusher repair in nigeria pulverising and screening of kaolin equipment used to mine kaolin mining plant kaolin flotation kaolin grinding mill i n india kaolin grinding equipment created by kaolin mining in georgia ...

China Clay Producers Association (CCPA) is organized to advance and encourage development and production of kaolinbased products, and to work with the people of Georgia in communities where the mineral is mined and products are manufactured.

Ore processing consists of removing impurities, engineering particle size and shape, and enhancing certain properties through thermal and chemical treatment. In addition to the technical aspects of mining and processing, the social, environmental, and economic impacts of kaolin production are managed at each stage of the mining life cycle.

【Process Introduction】 Dry wet separation are the two main Kaolin mining process of separation process is used to process Kaolin ore with higher white degree and lower sand and gravel content, this process characterized by easy operation and saving cost.

A process flow diagram for kaolin mining and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit Wet processing of kaolin begins with. Get More

kaolin mining and processing 5dd . Kaolinite is a clay mineral, part of the group of industrial minerals, with the chemical . of kaolinite dissolution and nucleation, because the thermal energy suffices to overcome the energy barriers involved in the nucleation process.

Kaolin is an important industrial mineral having numerous uses and requiring various market specifications. High brightness kaolin clays represent a continuing challenge to the producer. An advancement in this field of Kaolinite Clay Beneficiation has been a patented process developed by Minerals and Chemicals Philipp Corporation and termed Ultra Flotation.

Prospecting and Mining: ... The mining and processing of kaolin begins with exploration. Geologists study the earth''s surface, research literature and other data to identify land with potential kaolin deposits. Deposits of kaolin are located by drilling holes in the earth, which can range up to 200 feet in depth. ...

kaolin filter in mining process YouTube. Sep 28, 2012 · The pure kaolin features high whiteness, soft texture, high dispersion and suspension in the water, good plasticity, high bonding, good electrical insulating performance, high acid resistance, low .

Dec 12, 2003· According to the Geological Survey, more than 8 million metric tons of kaolin are mined from Georgia each year, with an estimated value of more than 1 billion. Georgia is by far the leading clayproducing state in America and is recognized as a world leader in the mining, production, processing, and application of kaolin products.

More than 4,400 Georgians are employed in the mining and processing of kaolin, making kaolin the state''s most important mineral industry with direct payroll and employee benefits exceeding 232 million annually. Additionally, in 1992, 103 million was paid to hundreds of other Georgians who work in businesses serving the kaolin industry.

Kaolin Processing Plant As a very important nonmetallic mineral, kaolin plays a very critical role in industrial using and is widely used in various industries such as ceramic, construction, paper making, filler material, painting, cosmetics as well as other applications.

WhatsApp)

WhatsApp)