energy savings in vertical roller mill

Contacts page classic with contact form in HTML. energy savings in vertical roller mill. We sincerely welcome you to contact us through hotlines and other instant communication ways.

WhatsApp)

WhatsApp)

Contacts page classic with contact form in HTML. energy savings in vertical roller mill. We sincerely welcome you to contact us through hotlines and other instant communication ways.

Energysaving Grinding Mill With Ce Certificate, Find Complete Details about Energysaving Grinding Mill With Ce Certificate,Energysaving Grinding Mill With Ce Certificate,Industrial Roller Mill,Vertical Roller Grinding Mill from Mine Mill Supplier or ManufacturerQingdao Shina .

Vertical Roller Mill Operation Grinding Mill. Vertical roller mill is Shanghai zenith industrial,in order to solve technical problems about mill with low yield, higher energy absorb the...

Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical roller mills and turnkey grinding mills.

An energy based comparison of vertical roller mills and . The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine respectively to 35% at 6000 Blaine.

In order to address grinding efficiency (defined as the increase in mass specific surface vs. net specific energy input) the energy consumption of two pilot scale vertical roller mills (200 mm and 670 mm table diameter) was compared to that of a sequence of laboratory comminution equipment covering the .

For cement companies, mining grinding system has become a key energysaving potential. In the cement grinding system, the major systems, vertical roller mill system energy savings of concern and recognition in recent years, the trend of concern without the .

efficiency energy saving vertical roller mill for cement slag raw material coal #; Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc.

The industry best in energyefficient grinding, the OK™ Mill uses five to ten percent less power than other vertical roller mills and 30 to 50 percent less energy than conventional ball mills. Easy operation and maintenance. Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill.

An energy based comparison of vertical roller mills and . The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine respectively to 35% at 6000 Blaine.

Vertical roller mill Wikipedia, the free encyclopedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral ... It is an energy efficient alternative for a ball mill.

Energy Saving Vertical Roller Mill For Cement/slag/raw Material/coal, Find Complete Details about Energy Saving Vertical Roller Mill For Cement/slag/raw Material/coal,Vertical Roller Mill,Vertical Mill For Cement,Roller Mill For Coal from Supplier or ManufacturerHenan Zhengzhou Mining Machinery Co., .

Lower energy consumption Lower energy consumption – The Decision • Rapid process dynamics are a challenge to operating a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order to make punctual ...

The high efficiency classifier can be used on LOESCHE vertical roller mills and also for all air swept grinding mills. The classifier is designed for central or without central material feed and can be used for all materials to be ground.

A critical review on energy use and savings in the cement (PDF . Article (PDF Available) in Renewable and Sustainable Energy Reviews 15(4): · May 2011 . Coal contribute major share of fuel used in cement industries. Russia 45 A ball mill or vertical roller mill (VRM) are used for a. Read More

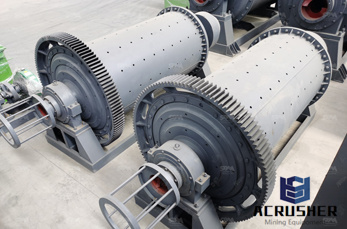

Energy Saving Slag Ball Mill/vertical Roller Mill For Ggbs Plant, Find Complete Details about Energy Saving Slag Ball Mill/vertical Roller Mill For Ggbs Plant,Ball Mil,Slag Vertical Mill,Ball Mill For Ggbs Plant from Supplier or ManufacturerHenan Zhengzhou Mining Machinery Co., Ltd.

Product Introduction. The vertical roller mill has been widely used and promoted in the electric power, metallurgy, chemical industry, nonmetal industry because the overall efficiency attributed to energysaving and low consumption is becoming

big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations. And thanks to our continuous refinement of the ATOX coal mill over the years, today''s leading airswept vertical roller mill is the .

Energy saving optimization of roller press Date: 09:55 Source: Views: From introduction to digestion and innovation, there is always a period of the beginning, we are very troublesome to maintain and repair the roll surface, in fact, we are troublesome to maintain stable and lasting operation.

Mar 10, 2015· The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine respectively to 35% at 6000 Blaine. For the siderite ore the energy savings show different behavior increasing from 48% at 3000 Blaine to 60% at 6000 Blaine.

Electrical Energy Conservation in Cement Plants in ... Intech Energy. The VRM (Vertical Roller Mill) is very efficient development over the conventional ball mill system saving about 30 to 35 per cent energy .

Energy saving effect is obvious for vertical roller mill News Date: 14:46:40. In the grinding system, the major systems, vertical roller mill system energy savings of concern and recognition in recent years, the trend of concern without the ball is a typical representative of the great debate. Some experts believe that the cement vertical mill, as a new, highly efficient, energy ...

The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine respectively to 35% at 6000 Blaine. For the siderite ore the energy savings show different behavior increasing from 48% at 3000 Blaine to 60% at 6000 Blaine.

Energy Saving Analysis of Cement Vertical roller mill and Discussion on Its Product Performance. Cement grinding process power consumption accounts for about onethird of the total power consumption of cement production process, therefore, reduce the cement grinding process power consumption has been an important issue for industry technical personnel research.

WhatsApp)

WhatsApp)