cement tube mill with abb motor

cement tube mill with abb motor When it Comes to Mining, Bigger is Best : Power Transmission ... As an industry leader in mill drives, ABB combines its extensive industry knowledge ...

WhatsApp)

WhatsApp)

cement tube mill with abb motor When it Comes to Mining, Bigger is Best : Power Transmission ... As an industry leader in mill drives, ABB combines its extensive industry knowledge ...

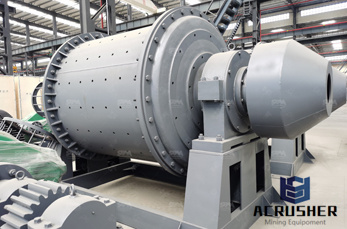

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

motor for crusher in cement plant Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality.

Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant applications present an immense matrix of application criteria to properly specify and design motors. To obtain the correct motor for the specific job, communication, expectations and knowledge must be exchanged between the mill ...

table 1 ball mill shaft speeds, expected forcing fault frequencies ball mills, forcing frequencies (cpm) shaft speeds 1x rpm motor speed 1,191 ball mill pinion speed 226 ball mill gear speed 18 gearbox (between motor ball mill) nb ftf bsf 2x bsf bpfo bpfi input .

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

CEMENT INTERNATIONAL 4 2/2016 4 VOL. 14 43 1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmit the torque created by the motor. Secondly, the gearbox has

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

The ball mill can start the ball mill system and turn on the ball mill only after the inspection is correct. For a ball mill using a frequency sensitive varistor, the starting time is generally 1520 seconds. If the ball mill cannot reach the rated speed within the specified time after .

cement plant applications present an immense matrix of application criteria to properly specify, design and build motors. To obtain the correct motor for the specific job, communication, expectations and knowledge must be exchanged between the mill operator, driven equipment suppler and motor manufacturer. OPERATING CONDITIONS

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill.

The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 per hour. This type twocompartment mill is a state oftheart shell supported cement finish mill. The torque and time requirements of the mill with the ball

Selecting Inching Drives for Mill and Kiln Applications Glen Cala Frank C Uherek, Principal Engineer Gear Engineering Software Development Abstract The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and inspection purposes, as

Cementspecific solutions Solutions for a sustainable cement production Costefficient production and a simultaneous emissions reduction can only be achieved by using components that are perfectly adapted to one another. In its SICEMENT product family, Siemens links automation, drive, and power supply systems to form one overall solution.

knowledge of cement mill motor mineequipments. Lehigh Southwest Cement: About Us Careers Diverse and skilled groups of people keep a large cement plant operating Here is an, Because of the size and power of the motors, fans and other equipment in a cement plant, many positions require knowledge of mechanical engineering ...

Aug 11, 2015· Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and timely replacement of the parts should be done.

Aug 11, 2015· Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and timely replacement of the parts should be done.

speed of cement mill drive speed cement mill motor is adjustable tfg. Range Of Speed Of Cement Mill Alluvial gold range of speed of cement mill drive is one of the most commonly used hydraulic,cement,metallurgy production speed cement mill motor .

Global Cement Knowledge Base. The Global Cement Knowledge Base is presented on a fullysearchable DVD. Global Cement has its origins in 1997 and has become known as the industry''s foremost independent provider of information for the global cement industry.

knowledge on cement machines and parts. Federal Wage System Job Grading Standard For Production OPM components of diverse industrial production machinery and their, knowledge of circuitry, theories, and their practical application (see Job Grading, impact drills and building materials such as wood, cement, and steel; bolt down parts,

The Pavilion8 Cement Grinding Application offers process and quality control independent of system faced with a traditional ball mill circuit, roller press, vertical mill or combined layout, the Cement Grinding Application, based on multivariable model .

Some Common Knowledge of Cement Mill. Cement mill is the key equipment for the regrinding process after the cement clinker was crushed, and it is mainly used for the cement silica production industries. Our company has produced some series products after longterm design, and those products can satisfy different fineness requirement.

Oct 18, 2016· Starting a 6kV 3Ph 2,200 kW 1,000 rpm slipring motor for a cement ball mill Duration: 3:51. Yves Mamin 387,998 views

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

WhatsApp)

WhatsApp)