stages on coal mining YouTube

Sep 02, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Sep 02, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

stage of processing of coal mining nannieleijtennl. the process of coal mining diagrams, Processing Coal this is usually a two stage process First the coal is crushed Learn More; coal mining process diagram More; Coal mining Wikipedia Coal mining is the process of extracting coal from the ground Coal is valued for its energy content, and ...

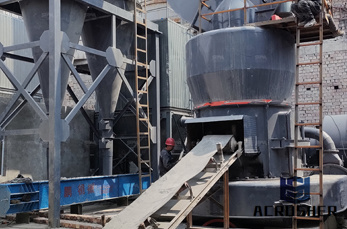

Coal processing involves crushing, screening and beneficiation. Processing is where coal is converted from runofmine (ROM) coal to a product that meets the customer''s requirements. Mined coal can include lumps. Crushing to a manageable size is required. Coal crushing can include a two stage process, dependent on deposit size.

Stage two of the coal formation process is lignite. Lignite forms when peat is put under considerable vertical pressure. It contains small amounts of plant matter and is very fragile so it must never be handled before burning. Bituminous coal is the third stage of coal production. The lignite continues receiving heavy vertical pressure until it ...

Dec 11, 2018· Coal mining (also called colliery) is the process of extracting coal from the ground''s surface or from deep underground. Coal miners literally raze entire mountain ranges to feed our insurmountable desire for cheap energy. There''s something brutally simple about coal mining.

How Explorers develop an exploration strategy, how they develop an exploration model and design an exploration program and select the optimal exploration tools to carry out that program. As usual of the talk will end with a series of learning points from this talk. There are two fundamental truths about the exploration industry; the first is that most exploration programs are doomed to failure ...

In roomandpillar mining, coal deposits are mined by cutting a network of ''rooms'' into the coal seam and leaving behind ''pillars'' of coal to support the roof of the mine. These pillars can be up to 40% of the total coal in the seam although this coal can sometimes be recovered at a later stage.

Jan 23, 2012· In modern times though, mining for gold is a much more intensive, yet sophisticated process. Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today. It''s largely a matter of technology and requires much expertise and elaborate equipment. Mining for gold today can essentially be broken down into 9 ...

Strip mining, removal of soil and rock (overburden) above a layer or seam (particularly coal), followed by the removal of the exposed mineral. The common stripmining techniques are classified as area mining or contour mining on the basis of the deposit geometry and type. The cycle of operations for ...

Coal mining, extraction of coal deposits from the surface of Earth and from underground. Coal is the most abundant fossil fuel on Earth. Its predominant use has always been for producing heat energy. It was the basic energy source that fueled the Industrial Revolution of the 18th and 19th

Dec 06, 2017· Coal mining. Mining operations can negatively impact water supplies, often with longlasting effects. The fundamental issue involves contamination of nearby rivers, lakes, and aquifers by what comes out of a coal mine—usually highly acidic water containing heavy metals like arsenic, copper, and lead. The process is known as acid mine happens when certain substances (typically ...

the mine property,although he or she may share those duties with those in the environmental fields. The fields of processing,refining,and fabricating are assigned to metallurgy,although there is often some overlap in the mineral processing area with mining engineering. 4 INTRODUCTION TO MINING

Some underground mines are 1,000 feet deep. To remove coal in these underground mines, miners ride elevators down deep mine shafts where they run machines that dig out the coal. Processing the Coal. After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site.

What is the mining process of coal? Quora. Apr 08, 2017· Thanks for A2A ! The selection of process for mining the coal deposit is attributed to various parameters, among those, the important ones are : 1 Dip of the coal deposit 2 Presence of geological discontinuiti 3 Capital available 4 Dept.

Jan 21, 2020· Rio Tinto sold its last coal mines in 2018, becoming the first mining major to go coalfree. Since then other mining companies have followed Rio Tinto''s lead and exited the coal industry; could the days of mining majors investing in coal be numbered? We round up the big names leaving coal .

Coal is a nonrenewable fossil fuel that is combusted and used to generate electricity. Mining techniques and combustion are both dangerous to miners and hazardous to the environment; however, coal accounts for about half of the electricity generation in the United States.

The mine site must be prepared for development. The headgear over the mine shaft needs to be built and the shaft sunk deep into the ground to transport people and materials in and out of the mine. Other required infrastructure includes structures for mining, milling and processing; and various workshops.

outside the mining area for placement and storage. In the Midwest, where the surface topography and coal seams are generally flat, it is common to employ area strip mining in which the fragmented overburden is placed directly by large draglines in the space created where coal has been mined ().In some situations in the eastern United States, a coal seam occurring near the top of mountains is ...

Recommendation: There should be renewed support for advanced coal mining and processing research and development to optimize use of the nation''s coal resources by increasing the amount of coal that is economically minable through technological advances .

Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities. Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP.. Stockpiles provide surge capacity to various parts of the CPP. ROM coal is delivered with large variations in production rate of tonnes per hour (tph).

Life Cycle Assessment of Coalfired Power Production Pamela L. Spath, Margaret K. Mann, and ... improvement stage of the assessment actually reduced environmental damage, or to comparative analyses ... often not necessary because topsoil is replaced during the mining process. Therefore, neither component

APPLICATION OF LIFE CYCLE ASSESSMENT (LCA) IN COAL MINING ... its use in the evaluation in mining processes and processing of mineral resources .

Stage Of Processing Of Coal Mining. Coal miners leaving an american mine at the end of a shift april 1974 surface coal mining in wyoming in the united states coal mine in bihar, india coal mine in frameries, belgiumoal mining is the process of extracting coal from the groundoal is valued for its energy content and since the 1880s, has been widely used to.

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production.

WhatsApp)

WhatsApp)