Crushing Ore to Recover Gold YouTube

Jun 11, 2012· Crushing a small ore sample to recover the gold buried inside. This sample was found in a lode vein in Marion County, Oregon. The ore is heavily laden with copper and pyrite along side of quartz.

WhatsApp)

WhatsApp)

Jun 11, 2012· Crushing a small ore sample to recover the gold buried inside. This sample was found in a lode vein in Marion County, Oregon. The ore is heavily laden with copper and pyrite along side of quartz.

Once the ores are fully roasted, and the sulfur is driven off, the extraction of the gold or silver from the ore is not especially difficult. Treatment of the roasted ores was done by normal methods such as amalgamation or cyanide treatment.

An ore. is a rock that contains enough of a metal or a metal compound to make extracting. the metal worthwhile, eg either: low grade ores contain a small percentage of the metal or its compound ...

This is not enough to make it commercially viable to extract the rock. Copper mines are only set up where there is more than 5 kg of copper per tonne of rock (% by mass). Ideally, the figure should be closer to 2%. The world''s largest copper ore deposits are found in .

Extraction of Silver by cyanide process and its uses. Silver also occurs both in combined state as well as in free state. The important ores of silver are: Argentite (Ag 2 S), Copper silver glance, Horn silver, Ruby silver. The silver ores are found along with gold ores in some parts of India.

Jul 07, 2020· ***copper remains in gold The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

with copper solvent extraction and. electrowinning (EW). Now approaching . ... Processing of gold ores has become a sitespecific choice of techniques and processes, depending upon mineralogical ...

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Extracting iron and copper Ores. Unreactive. metals. such as gold are found in the Earth''s crust. as the uncombined elements. However, ...

Quartzite is a harder stone than the stone bearing copper ores (malachite could be mined with flint tools, which it was during early periods), so greater effort had to be used to extract it. A Greek account from the 2 nd century BCE describes the Egyptian miners lighting fires over deposits of goldbearing quartzite to make the stone more ...

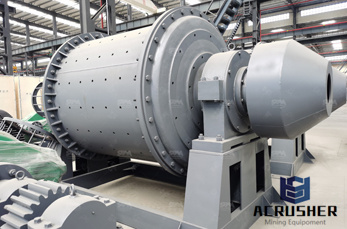

Ores are mined by blasting the earth with explosives or digging into rock with shovels and picks to extract the ore from the rock. Miners then process the copper or nickel ore to find cobalt by crushing the ore in primary cone crushers, using wet magnetic separators to separate the copper or nickel, and reducing it to mesh in a ball mill, which ...

Employ bioleaching for base metals, such as zinc, copper and nickel, or mineral bioxoidation to enhance extraction of gold and silver. Both methods rely on bacterium, such as hiobacillus ferrooxidans, to recover precious metals. For example, stack ore in piles 200 feet deep. Apply waterdiluted sulfuric acid to enable bacterium to grow.

May 24, 2020· S. Mithra Last Modified Date: 24 May 2020 . Bioleaching is the use of bacterial microorganisms to extract precious metals, such as gold, from ore in which it is an alternative to smelting or roasting, miners use bioleaching when there are lower concentrations of metal in ore and they need an efficient, environmentally responsible method to extract it.

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

Extracting copper from its ores. The method used to extract copper from its ores depends on the nature of the ore. Sulfide ores such as chalcopyrite ((CuFeS_2)) are converted to copper by a different method from silicate, carbonate or sulfate ores. Chalcopyrite (also known as copper pyrites) and similar sulfide ores are the commonest ores of ...

Extract copper and gold from lowgrade ores more efficiently Ore deposits are becoming increasingly complex to treat and grades continue to deteriorate in known reserves. For instance, approximately 1520 per cent of the world''s current gold production involves refractory ores that must be pretreated prior to downstream recovery by cyanidation.

My answer is to getting the gold free of copper, and it works for any alloy. 1. Raise the surface area/volume. Beat it until it is as thin as possible, or crush it and do your best to make dust/tiny fragments. 2. Put the whole of the sample into a...

*Cupellation is a refining process in metallurgy, where ores or alloyed metals are treated under high temperatures and controlled operations to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, present in the ore.

Hindustan Copper Ltd (HCL) said on Thursday it will soon be able to extract gold, sliver and silica sand from copper ore tailings. Santosh Sharma, Chairman and Managing Director, HCL, said an ...

Mar 24, 2016· Extraction of gold from ore revolves around smelting, not refining. I suggest joining the mining and prospecting forums to learn smelting or leaching techniques. Once you have made a good product from ore, then you can refine it to a pure metal.

May 01, 2017· The following sections cover the gold and copper extraction from ores and gold, silver and copper extraction form a concentrate. Goldcopper ores: goldcopper oxides. The gold extraction from leaching goldcopper oxides ore, containing ppm gold and % copper.

The Hunt methodcalls for the direct treatment of the ore with a solution of potassium cyanide to which ammonium hydroxide has been added. The gold is thus extracted together with some copper, and the metals are recovered by electrolytic precipitation, the gold, silver and copper falling to the bottom of the vats as a sludge.

Pour the acidandbleach mixture into the plastic bowl with the ore grains and stir. Allow four hours for the gold to dissolve, stirring every 20 minutes. The chlorine reacts with the gold inside the ore to form gold chloride. Filter the ore and bleach solution to remove all the impurities, such as soil and rock fragments.

Most gold ore now comes from either open pit or underground mines. The ores sometimes contain as little as 5/100 of an ounce of gold . Extracting iron and copper. Extracting iron and copper Ores. Unreactive. metals. such as gold are found in the Earth''s crust. as the uncombined elements. Copper is an example of this. Copper mostly occurs as ...

WhatsApp)

WhatsApp)